We provide high-quality organic iodine compound products for uses ranging from research and development to product manufacturing.

With our integrated development system, we can comprehensively meet a wide variety of needs, from contract manufacturing to proposal-based manufacturing.

Commissioned

manufacturing

Proposal-type

manufacturing

By performing everything in-house from the research and development stage, including sample synthesis, to the product manufacturing stage, where final products are supplied, we offer high-mix low-volume production, enabling the provision of high-quality products.

Inquiry

Confirm request

R&D

Pilot Test

product manufacturing

With the introduction of multi-product manufacturing equipment, multi-functional products can be manufactured in a large or a small amount by applying various reactions.

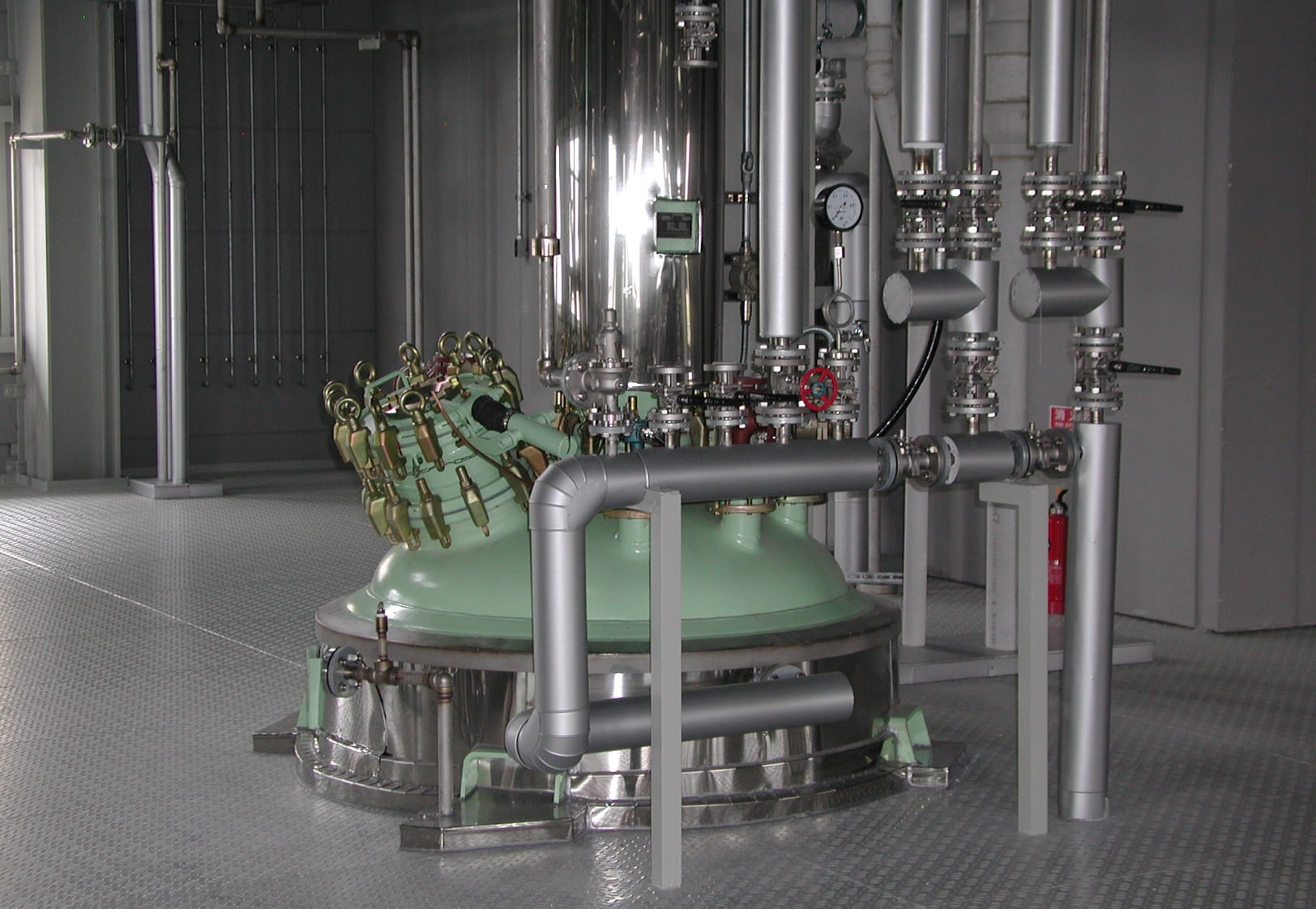

We have eight reactors with the capacity ranging from 2,000 to 5,000 liters. Various organic iodine compounds can be manufactured by controlling the special properties of iodine compounds.

This is the glass-lined conical dryer, which enables the offering of powder products free from foreign matter.

We offer high-quality organic iodine compounds by using the anti-corrosive centrifugal machines.

This is designed to remove BOD from wastewater discharged from the plant by coagulation sedimentation and biological treatment (aeration and membrane separation) to ensure eco-friendly water quality before discharge.

You can see it by scrolling horizontally.

You can see it by scrolling horizontally.

| Equipment name | Specification | Volume |

|---|---|---|

| Reaction vessel |

GL2000L

GL3000L GL5000L |

2units

2units 4units |

|

Distillation column

(Number of theoretical segments - 7segments) |

GL1000L | 1units |

| Oil pump | 10pa | 1units |

| Centrifuge |

30inch

42inch |

2units

1units |

| Conical dryer | GL2000L | 1units |

| Heat exchanger | GL 4〜20㎡ | - |

| Utility |

Heat source: steam, hot water

Cooling: cooling water, brine (-30°C~) Vacuum source: Oil rotary type, ejector type (steam/water combination), water-sealed type Others: Nitrogen, Argon |

- |