We were one of the first to start recycling iodine resources in

the 1960s in response to environmental regulations

and customer needs for economic efficiency.

We have established various processing methods,

including recycling solutions containing used iodine,

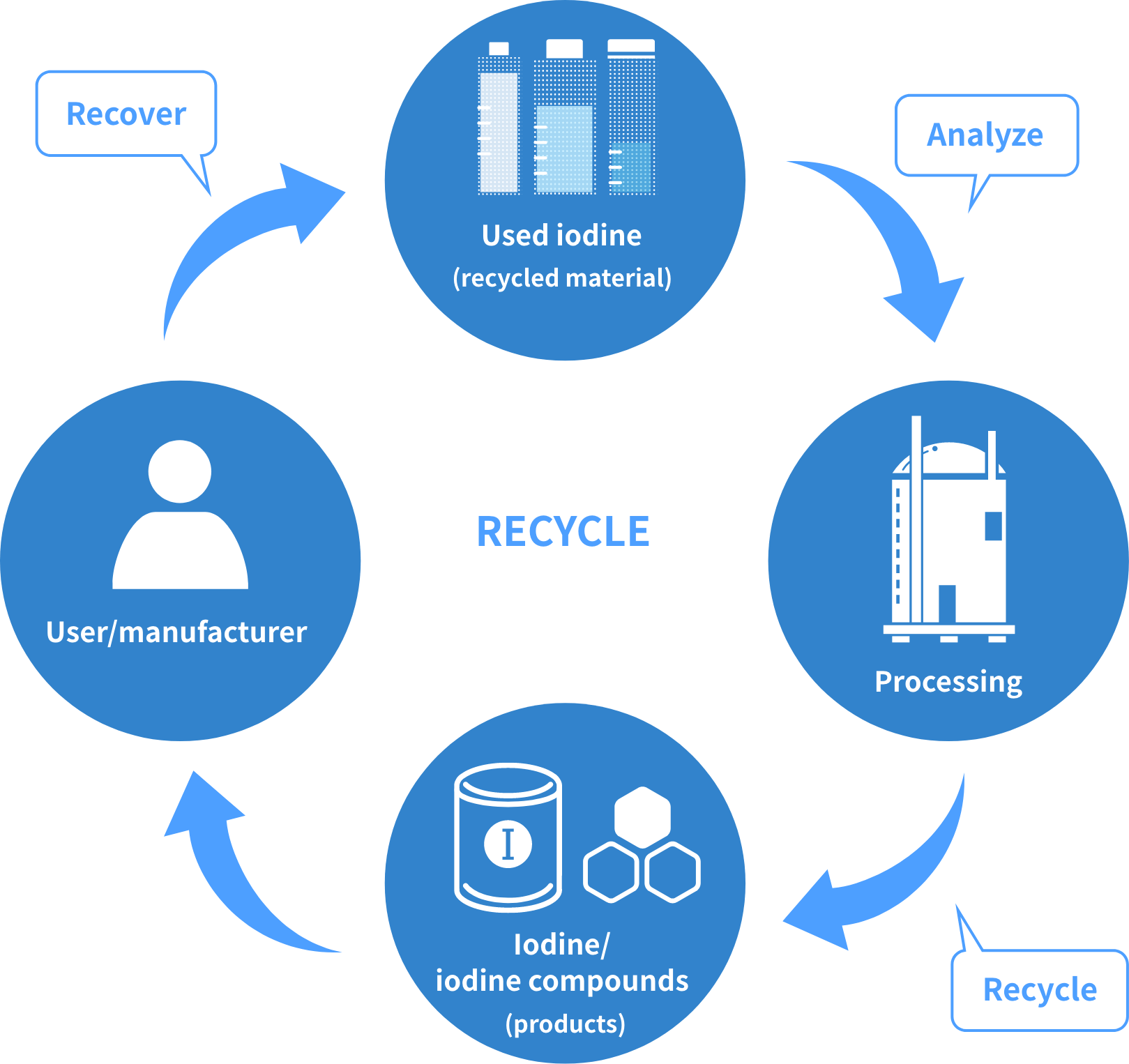

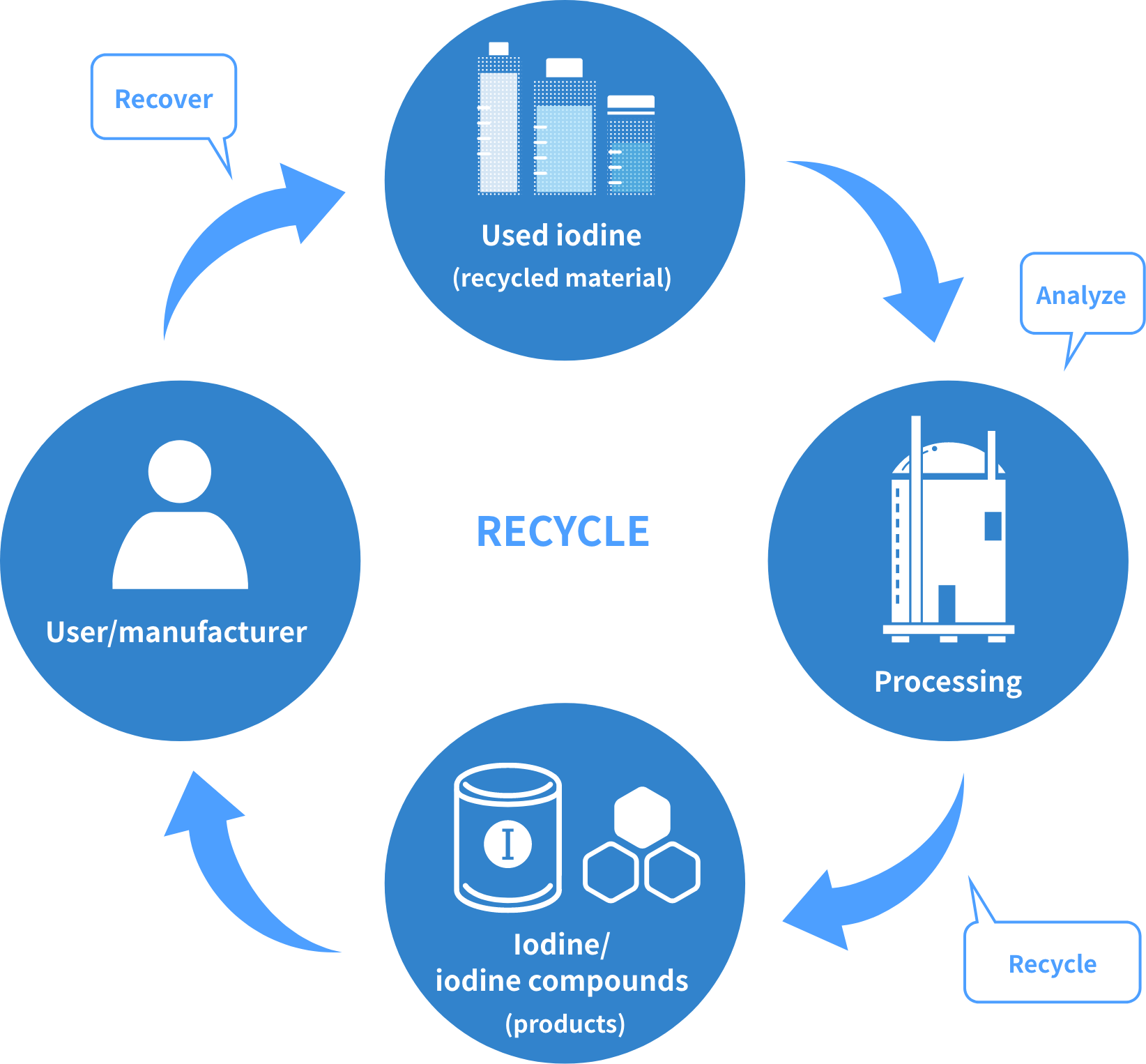

and have built a recycling system from manufacturing to sales, recovery, and recycling.

We are executing recycling operations of iodine and various useful elements by applying efficient recycling processes where our many patented technologies, equipment and long years of experience are used.

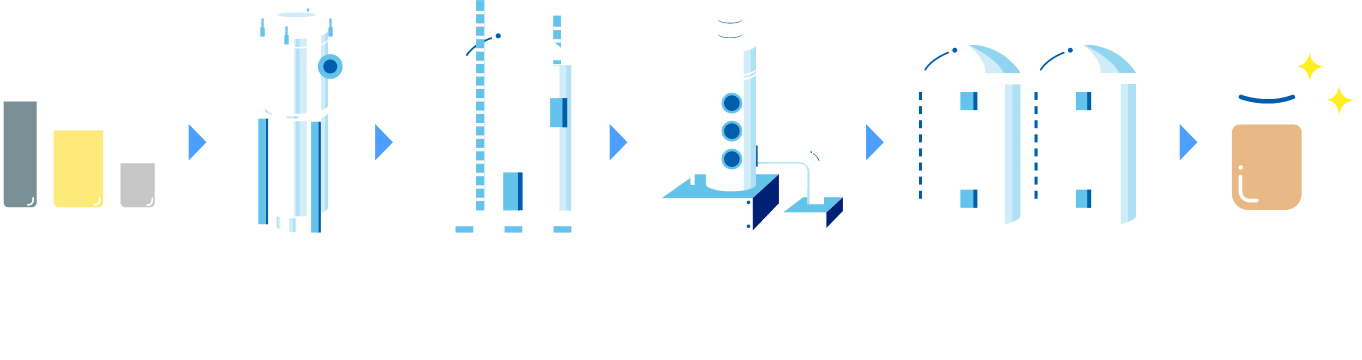

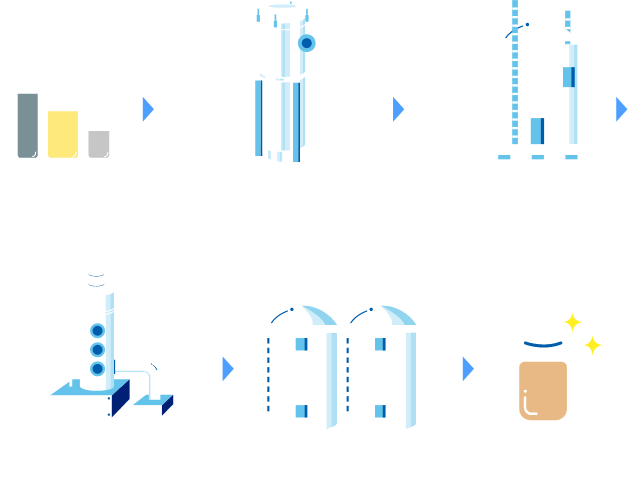

In 1992, we established the comprehensive iodine recycling technology based on our own high-temperature decomposition treatment technology (patent granted) where our accumulated know-how are fully utilized. Thus, we have established the efficient integrated manufacturing system covering the phases of raw material iodine manufacturing, iodine compound manufacturing and recycling of iodine.

Patents

Licenses

We promote recycling operations jointly with our users and we aim to build the efficient iodine recycling systems between the manufacturers and the users.

We examine the components contained and measure the form and content of iodine by using various analytical instruments. We then decide the processing method according to the form of iodine.

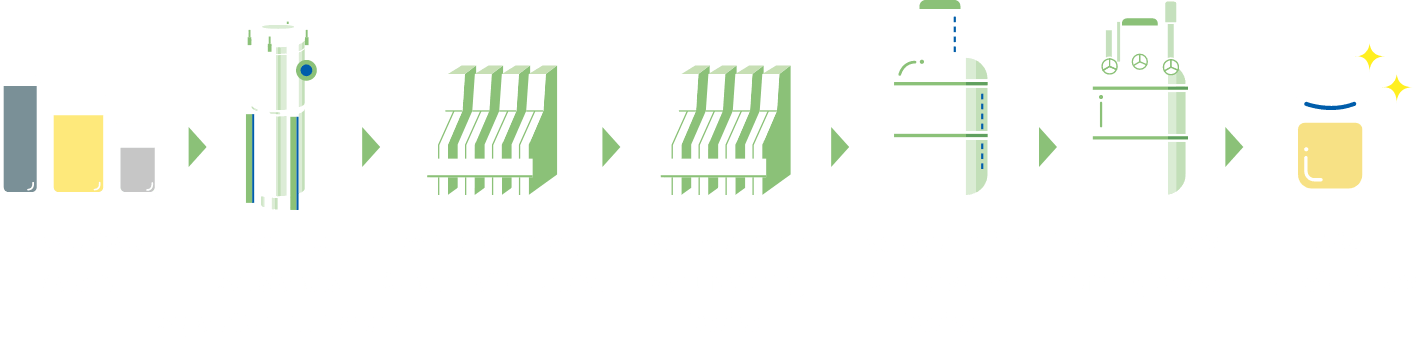

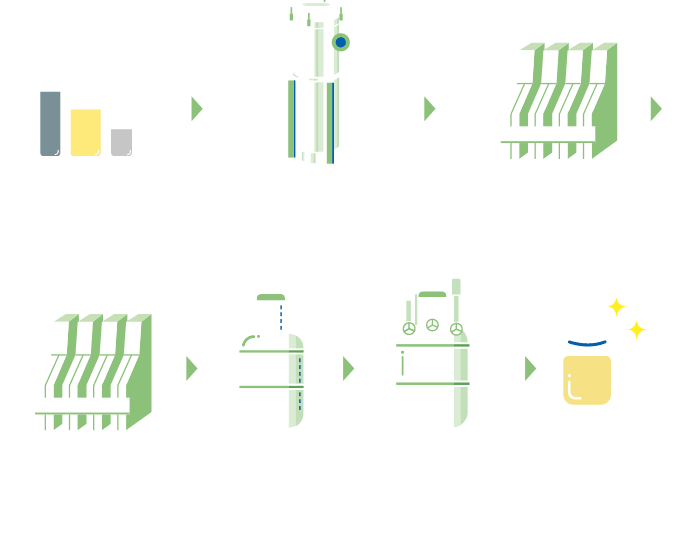

Waste liquids containing organic iodine compounds are first filtered to remove insoluble materials, then decomposed at high temperature, and the generated iodine is reductively absorbed and recovered.

The inorganic iodine solution is first filtered to remove insoluble materials, and then the iodide is extracted and concentrated with a dialysis membrane to be returned to the iodine production process.

We have established the integrated production system, which is capable of executing all manufacturing phases from the extraction of iodine to commercialization of the product.

The recycle raw materials containing organic iodine compounds are thermally decomposed in the high-temperature decomposition furnace to collect iodine.

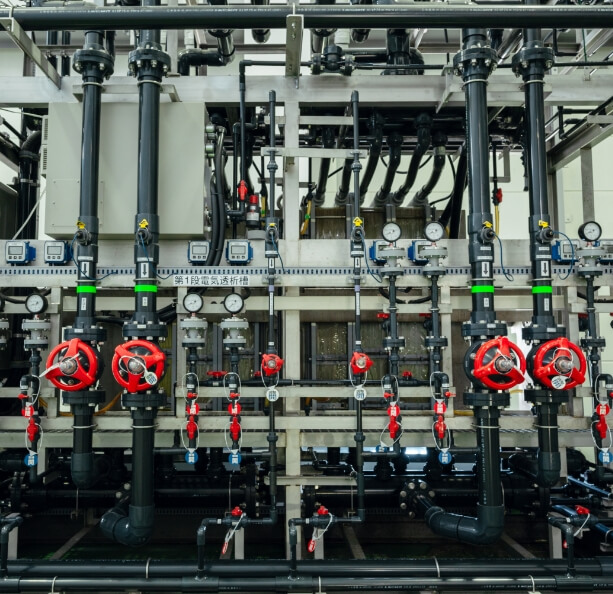

The high-temperature decomposition furnace and the electrodialysis device are controlled and monitored by CPUs, thereby ensuring safe operations.

With this equipment, it is also possible that iodine is selectively extracted from recycle raw materials to manufacture hydroiodic acid and the acid is converted into various iodine compounds.

Materials containing iodine including hazardous materials are burned torecover the iodine.

Materials containing iodine are dissolved or filtered, then dried to recoverthe iodine.

Technologies have developed us that enables manufacturing of hydroiodic acid by extracting and condensing iodide salts from recycle raw materials with electrodialyzer, thereby manufacturing various iodide salts.

The used materials containing iodine, which are collected from various fields, will be accepted by us. And the components and the treatment methods are evaluated by utilizing the accumulated analysis technologies, discussions with the generation cause party are conducted regarding the recycling method, and off-take price as the recycle raw material is calculated.

Please contact us if you have any questions about iodine recycling.

Contact us