We have been a pioneer in the production of iodine from the brine for the first time in Japan. Our long history gave us accumulated know-how.

In 1934, we developed the “copper method” to produce iodine from natural gas brine by using copper sulfate and iron sulfate, and succeeded in mass-producing iodine from natural gas brine for the first time in Japan.

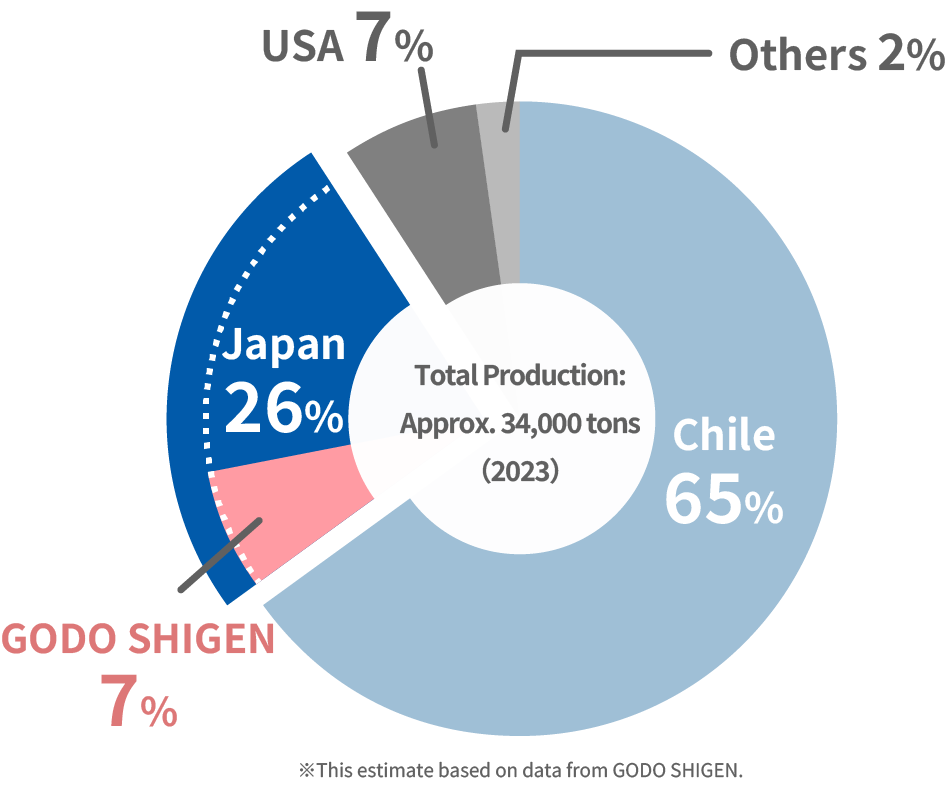

The annual global iodine production is about 34,000 tons, of which Japan produces some 9,400 tons, or 26%. Iodine is a valuable domestic natural resource that Japan, a resource-poor country, can export.

7% of Global Production

We manufacture high purity iodine with the blowing-out method and supply prilled form (spherical) products that are easy to handle.

We adopt the blowing-out method, which utilizes the vaporizable characteristic of iodine, and manufacture high-quality iodine from the brine pumped up from the ground. In addition, we realized supply of easy-to-handle products by shaping them to be prilled.

As a single plant, our plant boasts the largest production capacity in Japan, which uses the brine as the raw material, and is capable of supplying the product in bulk and in a stable manner.

After extracting iodine which is separated as a gas from the brine, the iodine is absorbed and reduced, and the brine concentration is condensed to about 1,000 times.

The extraction, condensation, and refining processes of iodine are controlled, monitored and automatically controlled by a central processing unit.

Impurities other than iodine are separated, refined and formed into prill by heating and melting iodine.

The green label attached on the packaging container earns high trust as the GODO Brand.